A BOM (for Bill of Materials, also known as a nomenclature in France) is an exhaustive list of all the components of a product, from the simple screw through the electronic components to the parts that make up the packaging. It is your shopping list for the creation of your product. It gathers all kinds of information and is used by various people involved in the project (design and engineering, document control, operations, manufacturing, purchasing, subcontractors, etc.). It is possible to indicate assemblies and sub-assemblies, but this is not systematic.

BOM or bill of material = document/list that gathers all the elements required to manufacture a product (components, assemblies or raw materials used).

What is the purpose of a BOM?

The BOM has a leading role in hardware project management. It allows to list all the parts needed to manufacture a product, but also to manage the procurement schedules, suppliers and obtain the cost of the final product.

If you outsource manufacturing activities, it is particularly important to create an accurate, rigorously revised and up-to-date BOM every time it is handed over to a manufacturer or supplier, otherwise you can expect some delivery delays.

How to create a BOM?

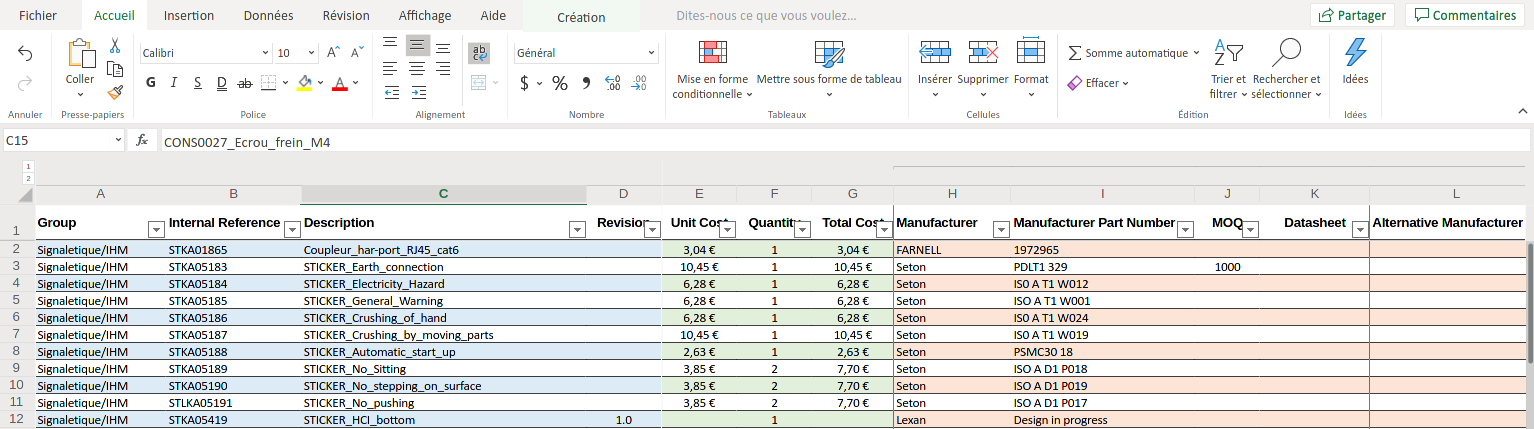

A good BOM is above all a complete BOM (of course) but also a BOM that you can apprehend from several angles. You will thus realize it in the form of a spreadsheet which will allow you to have a global view of the project oriented rather orders and quantities & in the form of a tree structure which will allow you to have a vision of the project by subsets. At Kickmaker, the tree structure is used for the design of the product assembly in 3D.

If you decide to use only the tree structure for your BOM, the risk is that you will end up with several names for the same part if it is used in several sub-assemblies. It is best to avoid creating duplicates as much as possible.

Good practice: make sure to correctly link the parts between the BOM and the 3D design (mech oriented + elec oriented = hardware) by using a correct and universal naming for the BOM and the parts tree.

What should be in the BOM?

So the BOM groups together all the elements required to manufacture a product. Each component, sub-assembly and raw material is identified thanks to a product code common to everyone (general codification and not specific to the project) & each product variant will have to be identified by a specific product code.

You can include several elements in your BOM:

–BOM level -assign to each part or assembly a number to indicate its place in the BOM hierarchy. This allows anyone with a good understanding of the BOM structure to decipher it quickly.

–Reference – assign each part or assembly a reference for quicker identification.

–Part’s name – save a unique name for each part or assembly. This will help you identify them more easily.

–Stage – revision or index of the part which allows a better management of the supplier relationship and the following of the evolutions of the part.

-Description – provide a detailed description of each part that will help you to distinguish between similar parts and more easily identify specific parts. Often the description is in the form of an image.

-Quantity – record the number of parts to be used in each assembly or sub-assembly to help guide purchasing and manufacturing decisions and activities.

-Type of procurement – specify how each part is purchased or manufactured (i.e. mass or custom-made) in order to improve the efficiency of manufacturing, planning and procurement activities.

-Reference Indicators – if your product contains printed circuit board assemblies (PCBA), you must include in your bill of materials (BOM) reference indicators that detail the location of the part on the board. Entering this information in the bill of materials can save you time and help you avoid confusion later.

-BOM notes – Allow everyone who interacts with your BOM to leave notes on the page.

You will also include in your BOM consumables such as screws, glues, tape or foams.

Concerning the 3D files attached to your BOM such as technical drawings or definition drawings (which are moreover linked to the BOM -> the part’s name on the drawing depends on the part’s name in the BOM), you must keep them in the same folder and associate these specific files to the BOM elements.

Versioning your BOM

Your BOM will undergo several modifications during product design. To make sure you keep track of these iterations, you will need to version the BOM and keep a written record of the different versions.

Thanks to Stéphane.T, Damien.M, Antoine.J & Quentin.D for their advice and feedback.

Want to know more about industrialiation? Read our quick introduction article