Engineer-tested hardware hacks: insider tips and trick

(By Kickmaker engineers)

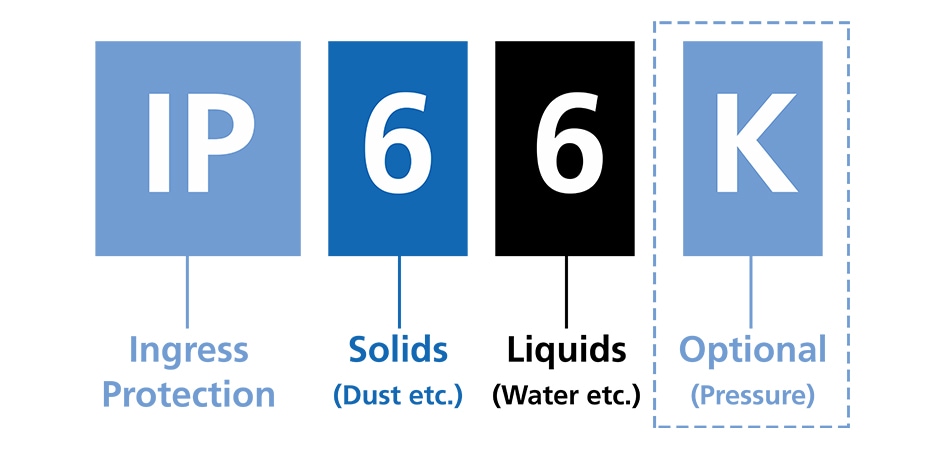

One of the crucial factors to consider before creating a product is its Ingress Protection level (commonly denoted as IPXX for the experts).

“Remember, Water finds a way. Always. If you don’t provide a path for water, water will assign one for you… and water is relentless. It won’t kindly avoid sensitive components, trust me.”

Underestimating this criterion can be costly, potentially leading to product rejection during laboratory validation tests, which occurs towards the end of the development process. As you’re probably aware, the closer you are to completion, the more expensive any necessary updates become.

Conversely, overprotecting your product can be financially burdensome. Not all levels of protection are equal, and finding the right balance between protection and cost is essential. For example, there’s no need to design a fully sealed enclosure for a IP22 toaster.

Remember, Water finds a way. Always. If you don’t provide a path for water, water will assign one for you… and water is relentless. It won’t kindly avoid sensitive components, trust me.

For a device with an IP67 rating enclosing electronics, you must ensure that water cannot enter at all. However, never underestimate your adversary; water can manifest itself in other forms, such as air humidity. As the temperature fluctuates inside your casing, condensation can occur, leading to unexpected water droplets. Try to anticipate their path too.

Another critical aspect to consider is water retention. Water often finds dead ends, where it can accumulate and slowly cause damage. You don’t want water to linger. When designing water paths in your device, identify and eliminate any potential dead ends to prevent water retention (like adding small holes).

Here’s a final tip: Before subjecting your device to IP validation tests, conduct your own tests on prototypes using simple methods like a shower, a bucket of water, or a sink. While not exactly the same conditions, these tests can provide valuable feedback and help identify potential breaches early in the process.

In a nutshell:

💧 Define the level of tightness required as early as possible.

💧 Do not underestimate the impact of sealing on product design

💧 Don’t forget water retention areas

💧 Test with the means at hand before sending out expensive lab tests

Recent Comments